7.1.15 Detailing of flat roofs

Flat roofs shall be detailed to ensure satisfactory performance.

Table 17: Flashings materials

| Flashing material | Guidance |

|---|---|

| Rolled lead sheet | Minimum code 4. BS EN 12588 |

| Aluminium and aluminium alloys | BS EN 485 and BS EN 573, 0.6-0.9mm thick and protected from contact with mortar by a coating of bituminous paint |

| Zinc alloys | BS EN 988 and 0.7mm thick |

| Copper | BS EN 1172, 0.6mm thick and fully annealed |

| Stainless steel | BS EN ISO 9445 parts 1-2 |

| Galvanised steel | BS EN 10142/3 |

| Proprietary flashing, including plastic and composite | Assessed in accordance with Technical Requirement R3 |

Notes

Where two metals are to be joined, they should be compatible and not cause bimetallic corrosion in that environment. Alternatively, they should be isolated from each other.

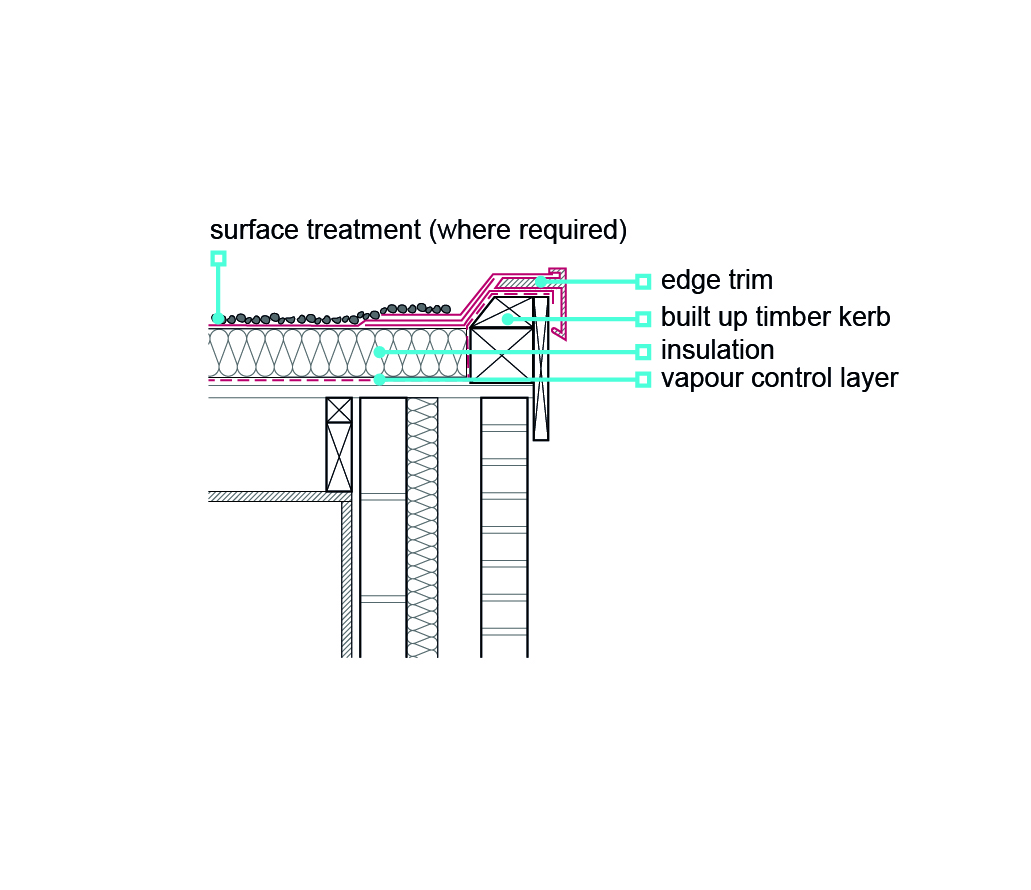

The following illustrations are intended as a guide to demonstrate the general principles of the flat roof detailing commonly used on flat roofs, terraces and balconies. Where indicated, the principles are applicable to other types of roof construction. Further information on specific waterproofing systems may be obtained from BS 6229 and BS 8217.

Concrete Decks

Upstands

Upstands may be fixed to the wall.

Upstands should be a minimum of 150mm high.

Similar details apply to inverted roofs with concrete decks.

Skirting to rooflights or ventilator kerb

Similar details apply to inverted roofs.

Allow for thickness of ballast to achieve a minimum 150mm upstand.

Twin-kerb expansion joint

Similar details apply to inverted roofs.

Timber decks

Mansard edge

Elements should be firmly fixed to prevent peelback in high winds.

Pitched roof abutment

Independent skirting detail

Upstand should be kept separate from wall, and allow for movement. Upstand should be a minimum of 150mm high above surface finish. Similar details apply to cold deck timber roofs.

Verge detail

Similar details apply to inverted decks.

Welted drip to external gutter

Inverted timber decks should be detailed to avoid insulation being lifted by wind suction and an alternative detail used.

Pipe passing through roof

Vapour control layer should be bonded to the waterproofing. Detailing of upstand and flashing is similar for all roofs.

Upstand to ventilator or rooflight kerb

Similar details apply to cold and inverted roofs. Allow for the thickness of ballast in inverted roofs, to achieve upstand dimensions.

Rainwater outlet

The opening should be properly trimmed.

The outlet should be at the lowest point in roof.

Ensure that the outlet is fixed securely to decking to prevent displacement by thermal expansion of rainwater pipe. Similar details apply to concrete roofs.

Inverted warm roof drainage outlet

Last updated: 2nd January 2024